Generative design in 3D printing is transforming the way we build, innovate, and create. Powered by artificial intelligence (AI), this new approach doesn’t just optimize structures, it pushes boundaries that traditional design would never dare explore. From groundbreaking architecture to life-saving medical devices, the fusion of AI and 3D printing is giving rise to creations that, frankly, humans couldn’t dream up. But what exactly is generative design, and how is it changing the world of 3D printing?

Let’s dive into how AI-driven design is revolutionizing industries and redefining human creativity.

What Exactly is Generative Design?

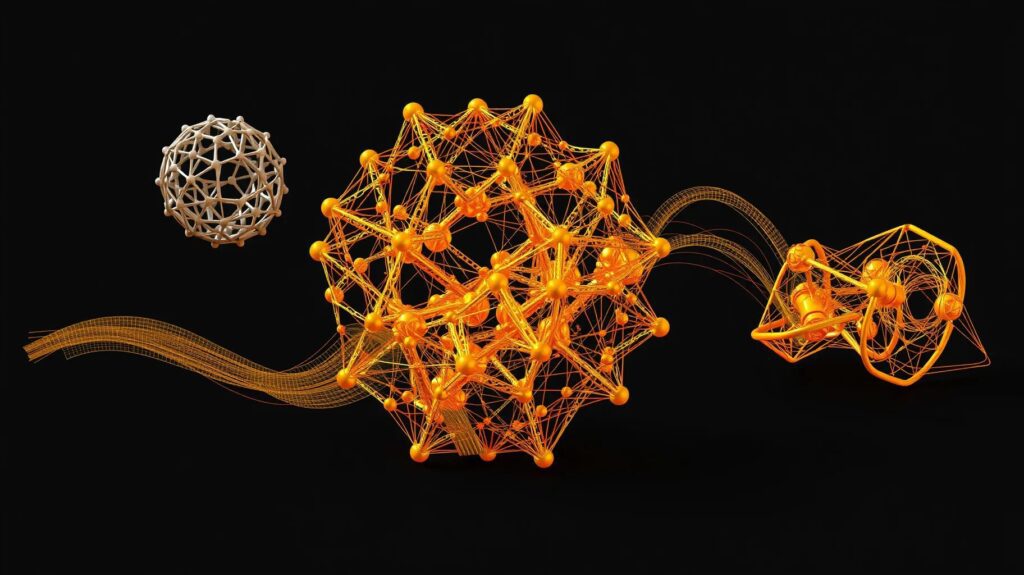

At its core, generative design is a process where designers set input parameters—such as materials, size constraints, and specific performance goals—while the AI algorithm explores every possible solution. It’s like handing over the brainstorming session to an AI, allowing it to churn out thousands of ideas in minutes, ideas that may be too intricate or complex for the human brain to conceptualize.

What makes it truly exciting is how it iterates—testing and evolving designs to be as efficient and optimal as possible.

The Evolution of 3D Printing: Enter AI

While 3D printing already has a reputation for pushing innovation, AI is turning that innovation into something even more extraordinary. Traditionally, 3D printing followed strict design rules: you fed it a design, and the printer spat out an exact replica. But now, with generative design, the printer doesn’t just follow instructions; it co-creates, almost as if the printer has developed a mind of its own.

The AI isn’t just optimizing—it’s innovating, offering up designs that look like they belong in science fiction rather than a product prototype.

Applications of Generative Design in Various Industries

- Aerospace: Think lighter, stronger airplane parts that are more fuel-efficient, thanks to AI’s design suggestions.

- Automotive: AI-driven 3D printing helps automakers reduce material waste and create more aerodynamic parts.

- Healthcare: Medical devices, prosthetics, and implants have benefited immensely from generative designs that conform uniquely to the user’s body.

Why Generative Design Makes Structures Stronger

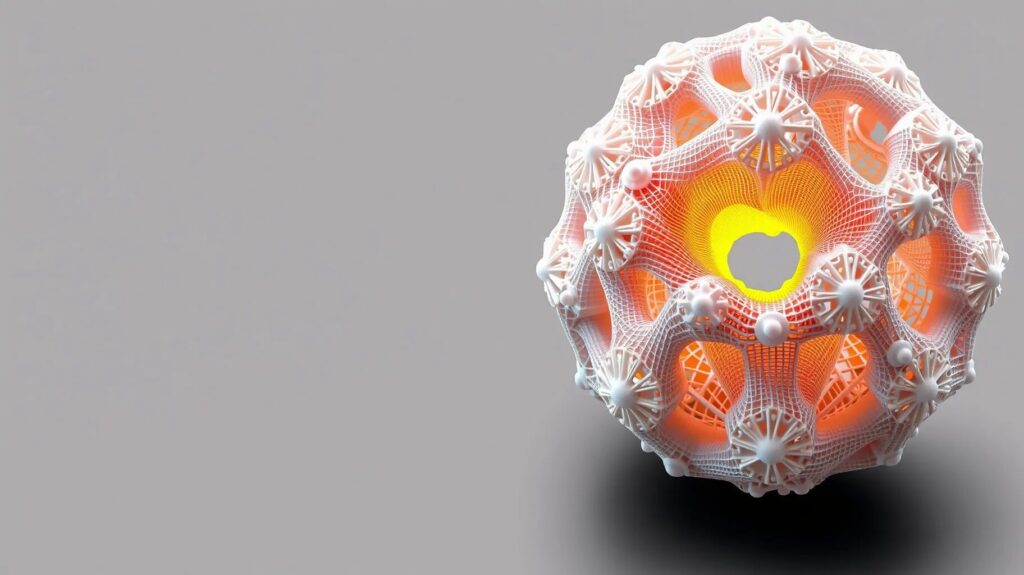

One of the major selling points of AI-driven design is its ability to create structures that aren’t just aesthetically pleasing but also strong and efficient. These designs are often inspired by nature—think of bone structures or tree branches. By mimicking these forms, generative design can reduce unnecessary material while reinforcing the parts that endure the most stress.

This nature-inspired approach, often called biomimicry, isn’t just about copying natural shapes but also about adopting their functional integrity.

Sustainable Solutions Through Generative Design

With sustainability becoming a global priority, the AI-driven approach of generative design offers new solutions. Imagine a future where every product is made with the least amount of material possible without compromising on quality. With AI controlling both the form and function of designs, less raw material is wasted, and end products are more energy-efficient.

In the long run, this contributes to lowering the environmental impact of mass production and manufacturing.

Breaking Traditional Design Rules

Generative design allows for more than just material efficiency. It breaks the mold—literally—of traditional design approaches. Designers are no longer restricted by straight lines or basic curves. The AI-generated shapes can be more organic, flowing, and intricate. The designs often look like something straight out of nature, with curves and holes in places where no human designer would think to put them.

This leads to innovations in product aesthetics and functionality that are unparalleled in traditional design methods.

Why Human Designers Still Matter

It’s easy to assume that with AI at the helm, human designers will eventually become obsolete. But that’s not the case. Instead, the role of the designer is evolving. Humans bring emotional insight, intuition, and a deep understanding of how products need to feel, look, and behave in the real world.

Generative design helps take some of the technical weight off human shoulders, letting them focus more on the bigger picture—ensuring that the product not only functions perfectly but also resonates with the user.

Accelerating Prototyping and Development

For industries, time is money. One of the major benefits of generative design and 3D printing is the speed at which companies can develop and iterate products. In the past, creating a prototype could take weeks, if not months. Now, with AI suggesting multiple designs at once and 3D printing bringing them to life within days, the prototyping phase has shrunk dramatically.

This rapid prototyping allows companies to test, tweak, and perfect their products at lightning speed, outpacing competitors.

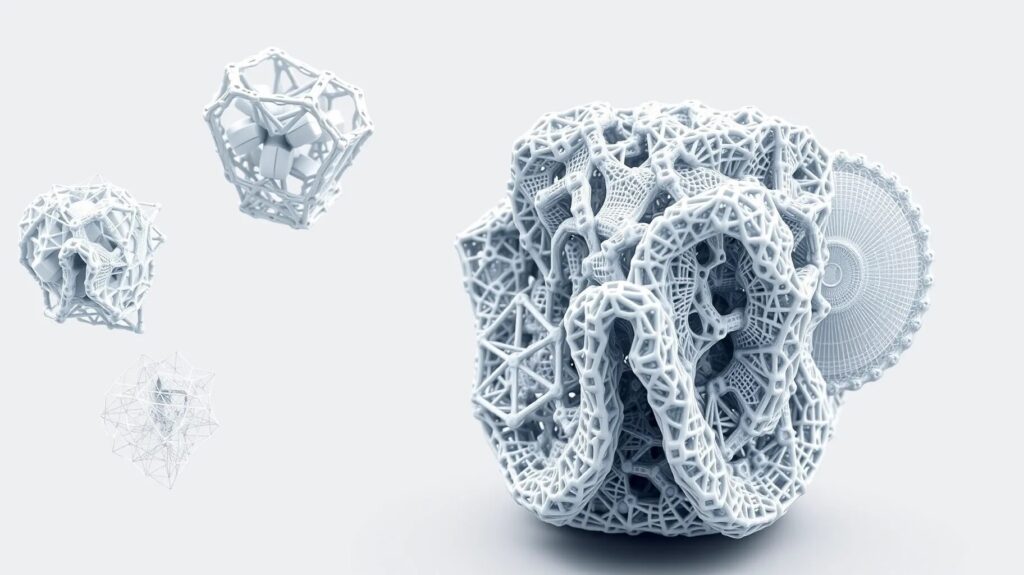

Complex Geometry Made Simple

Before AI-driven design, certain geometric shapes were simply impossible to produce. Traditional manufacturing methods rely on molds and basic templates, restricting the types of shapes that could be created. But generative design makes complex geometries achievable, and 3D printing turns them into tangible objects.

This complexity is especially beneficial in industries like aerospace and automotive, where lighter, more intricate parts translate into better performance.

The Future of Generative Design in Architecture

Architecture, too, is embracing this AI-powered shift. From stronger structural supports to beautifully organic facades, generative design is enabling architects to create buildings that are both aesthetically stunning and functionally superior. The designs that AI spits out may seem otherworldly at first glance, but they offer novel solutions to age-old challenges like load-bearing, wind resistance, and temperature regulation.

It’s no longer just about building a structure that stands—it’s about building a structure that thrives.

Customization for Individual Needs

One of the exciting promises of generative design is how it allows for true personalization. Imagine a world where every product, from your shoes to your car seat, is tailored specifically for you. Because AI can generate multiple designs based on user-specific parameters, customization is becoming more accessible, quicker, and affordable.

Whether it’s a custom-fit medical implant or a bicycle seat molded to your unique anatomy, the level of personalization generative design offers is unlike anything we’ve seen before.

Reducing Costs and Material Waste

There’s a misconception that AI and 3D printing technologies drive up costs, but in reality, they can lower them over time. By only using the precise amount of material needed, reducing prototyping times, and enabling faster iterations, companies can save on both raw materials and labor.

In fact, AI’s optimizations often lead to designs that require less material while still providing the necessary strength, thereby further reducing waste.

Revolutionizing the Supply Chain

The manufacturing industry’s supply chain is undergoing a transformation thanks to generative design and 3D printing. With fewer materials needed and faster production times, companies no longer need to stockpile huge amounts of inventory. Instead, they can print on demand, meaning fewer resources are spent on transportation, storage, and surplus materials.

This “just-in-time” production model could redefine global manufacturing, making it leaner, faster, and far more efficient.

The Limitless Potential of AI in Design

It’s clear that generative design and 3D printing represent only the beginning of what’s possible. As AI continues to evolve and improve, the designs of tomorrow could make today’s seem primitive. From architecture to product design, we are only scratching the surface of AI’s capabilities.

Imagine the day when AI isn’t just optimizing the design but creating the inspiration for it.

The Human-AI Collaboration

Ultimately, generative design isn’t about replacing human creativity but enhancing it. With AI doing the heavy lifting of calculations and iterations, designers have more freedom to experiment, innovate, and express their vision. It’s not a battle between man and machine; it’s a partnership where each brings unique strengths to the table. Together, they create what neither could have achieved alone.

Challenges of Generative Design in 3D Printing

Despite its groundbreaking potential, generative design in 3D printing isn’t without its challenges. One of the biggest hurdles lies in the complexity of the designs themselves. While AI-generated designs are often intricate and highly optimized, they can sometimes be so complex that they push the limits of what even the best 3D printers can handle.

Another issue is the material constraints. Though generative design can suggest the most efficient shape for a part, the material choices for 3D printing may limit how well those designs can be realized. For instance, certain intricate lattice structures may be perfect in theory but could break under stress if printed with weaker materials.

Finally, there’s the question of software integration. Many traditional design tools are not yet fully compatible with generative design workflows, creating friction between concept and execution.

The Learning Curve for Designers

For designers, embracing AI-powered generative design requires learning new tools and adapting to a different way of thinking about the creative process. This can be intimidating, especially for those accustomed to more hands-on, traditional methods. Instead of meticulously designing each aspect of a product, the designer must become comfortable with setting constraints and goals, then letting the AI explore possibilities.

However, once this learning curve is overcome, many find the results well worth the effort. AI-driven design tools provide immense creative freedom, allowing designers to explore ideas they might never have thought possible on their own.

AI’s Role in Predictive Design

One of the next frontiers of AI in 3D printing is predictive design. Right now, AI in generative design is reactive—adjusting based on input and constraints. But what if AI could predict design flaws before they happen? That’s where predictive algorithms come into play.

These algorithms would not only suggest optimal designs but also predict how those designs will perform under real-world conditions. Imagine printing a chair that, before even being physically produced, has already been tested in virtual simulations for strength, durability, and comfort.

This could significantly reduce trial-and-error prototyping, saving industries vast amounts of time and resources.

Ethical Considerations and AI in Design

As with any powerful tool, the integration of AI in design brings up important ethical questions. For instance, if AI can create proprietary designs, who truly owns those designs? Is it the designer who input the constraints, the company providing the AI software, or the AI itself?

Additionally, there’s the concern about job displacement. While AI-driven generative design empowers human designers in many ways, it may also reduce the demand for certain manual design jobs. The industry will need to find ways to balance these shifts, ensuring that workers can transition into roles that leverage their creative talents alongside AI tools.

How Generative Design is Shaping the Future of Manufacturing

The manufacturing industry is undergoing a quiet revolution thanks to the possibilities presented by generative design and 3D printing. What used to take massive industrial machines and countless hours of manual labor can now be automated, optimized, and streamlined by AI.

This shift isn’t just about speeding up production. It’s about creating more innovative, lightweight, and efficient products that can be manufactured anywhere in the world. With the advent of on-demand 3D printing, the need for giant centralized factories could diminish, as local production becomes increasingly viable.

This localized approach not only reduces the carbon footprint of shipping and logistics but also empowers smaller businesses to compete with major manufacturers.

The Democratization of Design

With the rise of generative design and 3D printing, we are seeing the democratization of design. Traditionally, high-level design tools and manufacturing capabilities were only accessible to large corporations or elite design firms. Now, with the introduction of AI-powered tools, even a small startup or solo designer can create cutting-edge, optimized products.

This opens up incredible opportunities for innovation and creativity. With access to these tools, creators from all walks of life can enter industries that were once closed off to them due to high costs or technological barriers.

Imagine a future where a teenager in their garage can design and print their own product prototypes using AI-assisted design tools, with the same level of complexity and innovation as a multi-million dollar company.

Real-World Case Studies of Generative Design Success

Let’s take a look at some real-world examples where generative design and 3D printing have made an impact:

- Airbus: The aerospace giant used generative design to reduce the weight of their airplane partitions. These AI-generated designs were structurally optimized, cutting down material weight by 45%. This not only saves on fuel but also reduces the environmental impact of each flight.

- Under Armour: The athletic company embraced generative design to create their UA Architech shoe. By using AI to generate the most efficient lattice structure for the midsole, the result was a shoe that offered unparalleled support and performance.

- GM: General Motors worked with AI to redesign seat belt brackets for their cars. By using generative design, they were able to create parts that were 40% lighter and 20% stronger, improving both safety and fuel efficiency.

These examples show that generative design isn’t just a futuristic concept; it’s already being put to use in various industries with transformative results.

Overcoming the Skepticism Around AI in Design

There’s no denying that AI is sometimes met with skepticism. Some worry that allowing machines to generate designs could lead to a loss of creative expression or human uniqueness. Others are concerned about over-reliance on algorithms that might produce solutions without fully understanding human needs.

But the truth is, AI in design isn’t about taking over human creativity—it’s about expanding it. Designers still play a critical role in shaping the outcomes by defining the goals and constraints. In fact, AI can empower designers to experiment and push boundaries in ways that were previously impossible.

Instead of replacing human imagination, AI-driven design can enhance it, enabling creators to explore new frontiers and find inspiration in unexpected places.

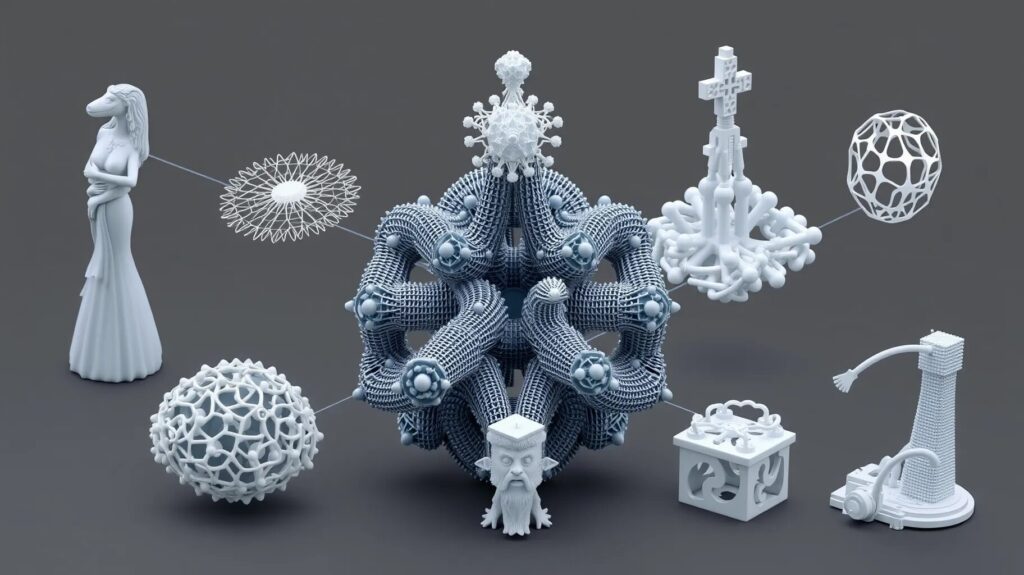

The Intersection of Art and Technology

One of the most exciting aspects of generative design is how it blends art and technology. In some cases, the AI-generated designs look more like modern sculptures than functional parts. These intricate forms challenge the very notion of what design should look like, opening the door for aesthetic experimentation.

This fusion of creativity and functionality is particularly powerful in fields like architecture, product design, and fashion. Imagine wearing a garment that’s not only stylish but also tailored to your body with pinpoint precision, thanks to AI.

In many ways, the future of generative design could redefine the relationship between form and function, allowing us to create products that are as beautiful as they are practical.

The Next Leap: AI Creating with Minimal Human Input?

The natural question then becomes—what’s next? If AI can already optimize and generate complex designs, could there come a time when it’s creating entirely on its own, with minimal human input? We may be closer to this reality than we think.

As AI continues to evolve, it’s not hard to imagine a future where machines don’t just iterate on existing designs but also generate completely novel concepts without any human intervention. Of course, this raises philosophical questions about the nature of creativity and whether something truly unique can be produced by an algorithm.

But no matter what the future holds, one thing is certain: AI and generative design are reshaping the world of 3D printing in ways we’re only beginning to understand.

Generative Design for Enhanced Sustainability

One of the most compelling reasons to embrace generative design in 3D printing is its potential to dramatically improve sustainability. Traditional manufacturing processes often involve wasteful practices, such as using more material than necessary or creating excess parts that end up discarded. Generative design, on the other hand, ensures that every ounce of material is used efficiently.

By simulating multiple iterations of a design, AI can optimize products to be lighter, stronger, and more resource-efficient. This not only cuts down on material waste but also decreases energy consumption in the manufacturing process. Companies that adopt these practices can reduce their environmental impact while also lowering costs, making it a win-win for both the business and the planet.

Take the automotive industry for example: AI-optimized parts are often lighter than traditionally designed ones, leading to more fuel-efficient vehicles. This small change can have a profound impact on carbon emissions over the lifespan of the product.

Impact on Supply Chain Efficiency

The integration of AI and 3D printing in generative design goes beyond just the product. It’s also about the systems that bring those products to life—namely, the supply chain. Traditional manufacturing often requires significant logistical planning, with raw materials and parts being shipped from various locations, stored in warehouses, and assembled on-site. This method is not only time-consuming but also energy-intensive, with countless resources spent on transportation and storage.

Generative design and on-demand 3D printing can revolutionize this process. Instead of relying on complex supply chains and large inventories, companies can print parts locally, reducing both lead times and transportation costs. This creates a more agile, cost-effective, and environmentally friendly supply chain model.

Additionally, with generative design, each part is designed to be as efficient as possible, minimizing the number of components and materials needed. This reduces assembly time and makes the entire process leaner, helping companies become more competitive in the marketplace.

The Role of Cloud Computing in Generative Design

A major factor that enables the scalability of generative design is cloud computing. Without the massive computational power of the cloud, running thousands of design iterations would take days, if not weeks, on standard hardware. But with cloud-based AI algorithms, designers can run simulations across multiple servers in parallel, cutting the time required to generate optimized designs significantly.

This real-time processing power allows for instant feedback and rapid prototyping, enabling designers to tweak and adjust their constraints on the fly. Cloud platforms also make collaboration easier, allowing teams across the globe to work together seamlessly on a single project, whether they’re developing a new medical implant or designing cutting-edge aerospace parts.

The flexibility of the cloud allows companies to scale their design efforts up or down depending on the project’s needs, making it cost-effective for businesses of all sizes.

AI-Generated Aesthetics: Form Meets Function

One of the fascinating by-products of AI-driven generative design is the unique aesthetics that emerge from the process. Because AI is driven by functional requirements, rather than aesthetic ones, the designs it produces often have a futuristic, almost alien look. These designs frequently feature intricate, organic shapes that are both efficient and beautiful.

These new forms challenge traditional ideas of what “good design” looks like. Historically, human designers have had certain biases and preferences when it comes to form—symmetry, straight lines, and simplicity. But AI has no such biases. It only cares about optimizing performance, and the results can be stunning in their unexpectedness.

This blending of form and function has made AI-generated designs increasingly popular in fields like architecture and furniture design, where the final product needs to be both functional and aesthetically pleasing. Architects are now using generative design to create structures that not only look like modern art but also have superior structural integrity and energy efficiency.

Humanizing AI-Driven Design

While generative design offers exciting possibilities, there’s also the question of how to maintain a human touch in AI-driven creations. One risk of relying too heavily on AI is that designs could start to feel too machine-like, devoid of the emotional and cultural nuances that make products truly resonate with users.

However, many designers are finding ways to blend the best of both worlds. By using AI to handle the technical aspects of the design process, they can focus more on the user experience and the emotional qualities of a product. The result is a collaboration where AI takes care of the heavy lifting, while human designers bring the heart and soul to the project.

AI-Driven Customization and Personalization

In a world that increasingly values personalization, AI-driven generative design is making mass customization not just possible but practical. Whether it’s a custom-fit prosthetic limb, a personalized phone case, or a tailor-made bicycle, AI can take individual preferences and specifications into account to create one-of-a-kind products.

Take custom medical devices, for example. By scanning a patient’s body, AI can generate designs that perfectly conform to their unique anatomy. This ensures that the device is not only comfortable but also more effective. Similar processes are happening in the fashion industry, where 3D printing and AI are being used to create shoes, clothing, and accessories that are tailored to fit each person’s body perfectly.

Personalized products aren’t just a novelty—they improve functionality, comfort, and user satisfaction. This is especially important in fields like healthcare, where a custom-fit prosthetic or orthotic can drastically improve a patient’s quality of life.

Generative Design in Space Exploration

One of the most thrilling applications of generative design and 3D printing is in space exploration. Space missions demand lightweight, durable, and highly efficient components due to the constraints of fuel, space, and extreme environmental conditions. Traditional manufacturing methods often fall short of meeting these demands. However, AI-driven generative design has the potential to create parts that are perfectly suited for the challenges of space.

NASA and other space agencies are already exploring the use of 3D printing for in-space manufacturing, meaning parts could be designed and printed directly on the spacecraft or at a lunar base, reducing the need for costly supply runs from Earth. The optimized parts would be lighter, saving fuel, and their designs would be robust enough to withstand the rigors of space travel.

Generative design could even play a role in building habitats on other planets. By using local resources like lunar or Martian soil, combined with AI-optimized designs, we could potentially 3D-print structures on these distant worlds, paving the way for sustainable human habitation beyond Earth.

The Future of Generative Design: Unimaginable Horizons

As the technology behind AI-driven generative design continues to evolve, the potential applications seem limitless. We’ve already seen how it’s transforming industries like automotive, aerospace, and architecture. But the real excitement lies in what’s yet to come.

Imagine a future where AI not only assists in designing products but also helps solve some of the world’s most pressing problems—like creating affordable housing for everyone, designing sustainable energy systems, or even developing new medical treatments that are personalized to an individual’s genetic makeup.

The future of generative design will likely push the boundaries of human imagination. With AI doing what humans can’t—exploring countless possibilities in seconds—designers will be free to focus on the vision, while AI handles the execution.

In the end, generative design and 3D printing aren’t just technologies; they’re tools that will redefine what’s possible. By embracing these innovations, we can create a future that’s not only more efficient but also more creative, sustainable, and human than ever before.

FAQ: Generative Design in 3D Printing

1. What is generative design?

Generative design is an AI-driven design process where designers set specific constraints (e.g., materials, weight, performance goals), and the AI explores numerous design possibilities to generate optimized solutions. It’s like having a digital brainstorming assistant that suggests innovative shapes and structures humans might not envision.

2. How does generative design work with 3D printing?

In 3D printing, generative design allows for the creation of intricate, optimized designs that can be directly printed. AI produces structures based on performance criteria (such as strength, weight, and material usage), and 3D printing brings these designs to life, producing parts that are often stronger, lighter, and more complex than traditional designs.

3. What industries are using generative design?

Generative design is being used in several industries, including:

- Aerospace (lighter, more fuel-efficient parts)

- Automotive (optimized components for fuel efficiency and safety)

- Healthcare (custom prosthetics, implants, medical devices)

- Architecture (stronger, more sustainable building designs)

- Consumer Goods (customized, optimized product designs)

4. What are the benefits of using generative design in 3D printing?

Generative design offers numerous advantages, including:

- Optimized performance: AI-driven designs are often stronger, lighter, and more efficient than human-designed ones.

- Material efficiency: Designs use only the necessary amount of material, reducing waste.

- Faster prototyping: Multiple iterations can be created quickly, speeding up the design and manufacturing process.

- Complex geometries: Designs can be incredibly intricate, with forms that would be impossible to achieve using traditional manufacturing methods.

- Sustainability: Reducing material waste and energy use contributes to more environmentally friendly production.

5. Does generative design replace human designers?

No, generative design enhances, rather than replaces, human creativity. Designers set the parameters and goals, and the AI explores possibilities based on those criteria. The human element is still essential for guiding the process, ensuring that the resulting product aligns with aesthetic, emotional, and functional needs.

6. How does generative design improve sustainability?

Generative design optimizes material use by reducing waste and creating efficient structures that use less raw material. This means less energy is required during production, leading to lighter products (in applications like automotive and aerospace) that reduce fuel consumption and carbon emissions.

7. What challenges are associated with generative design?

Some of the key challenges include:

- Complexity: AI-generated designs can be difficult to print due to their intricate geometries.

- Material limitations: While AI may optimize a design, the materials available for 3D printing may limit how well that design can be realized.

- Learning curve: Designers must learn to trust and work with AI tools, which may be intimidating for those used to traditional design methods.

8. How does generative design enable customization?

Generative design allows for true mass customization by tailoring products to specific user needs. For example, a prosthetic limb can be designed to perfectly fit an individual’s anatomy, or a bicycle seat can be optimized for the user’s comfort. AI can quickly generate designs based on unique user data, offering personalization at scale.

9. What role does AI play in predictive design?

In the future, AI could evolve into predictive design, where algorithms don’t just optimize designs based on set parameters but also predict how a product will perform under various conditions (e.g., stress, temperature changes) before it’s even made. This could reduce the need for physical testing, saving time and resources.

10. Is generative design more expensive than traditional design?

While the initial setup for generative design tools may have higher costs, the long-term savings in material, time, and labor often offset this. Companies can produce parts with minimal material waste, streamline the design process, and reduce prototyping costs, making the overall process more cost-effective.

11. What software is used for generative design in 3D printing?

Some of the popular software tools used for generative design include:

- Autodesk’s Fusion 360 (generative design and manufacturing platform)

- SolidWorks (3D CAD software with generative design capabilities)

- nTopology (advanced generative design and simulation tools)

- Siemens NX (integrated CAD/CAM/CAE software)

12. Can generative design create real-world products, or is it only for prototyping?

Generative design is already being used to create real-world products across industries. From airplane parts and customized footwear to medical devices, companies are using generative design for both prototyping and end-use manufacturing.

13. How does generative design improve product performance?

By running thousands of iterations, AI optimizes the design to meet specific performance criteria such as strength, weight, and durability. This results in parts that are often much lighter and stronger than traditionally designed ones, improving performance in applications like aerospace and automotive.

14. What are the ethical concerns related to AI in generative design?

Some of the ethical concerns include:

- Intellectual property: Who owns the design—the designer, the company, or the AI that generated it?

- Job displacement: There’s concern that AI-driven design could reduce the need for certain design jobs, although it’s more likely to evolve existing roles.

- Over-reliance on AI: Designers must balance trust in AI-generated designs with ensuring that human factors, such as user experience and aesthetic appeal, are still met.

15. What’s the future of generative design?

The future of generative design holds immense potential, from building sustainable homes to creating space exploration components. As AI evolves, it will likely become more predictive, potentially generating entirely new concepts with minimal human input. The merging of generative design with 3D printing could lead to unimaginable innovations in product design, manufacturing, and engineering.

Resources for Learning More About Generative Design in 3D Printing

If you’re interested in diving deeper into generative design and its intersection with 3D printing, here’s a list of valuable resources, from online courses to articles, books, and tools. These will help you explore the cutting-edge technology driving the future of design and manufacturing.

Online Courses & Tutorials

- Autodesk Generative Design for Manufacturing

Platform: Autodesk University

Description: Free tutorials and courses on Fusion 360’s generative design capabilities, walking through both fundamentals and advanced techniques for 3D printing and manufacturing applications. - Generative Design for Additive Manufacturing

Platform: Coursera

Description: A comprehensive course covering generative design principles with a focus on additive manufacturing (3D printing). Learn how to leverage AI for optimizing designs and producing intricate geometries. - nTopology Learning Center

Platform: nTopology

Description: A collection of webinars, tutorials, and use cases for generative design and advanced simulation, focused on industrial applications and product development. - Fusion 360 Generative Design Bootcamp

Platform: LinkedIn Learning

Description: A practical introduction to Autodesk Fusion 360, including how to use generative design tools for creating optimized structures ready for 3D printing.

Books

- Generative Design: Visualize, Program, and Create with JavaScript in P5.js

Authors: Hartmut Bohnacker, Benedikt Gross, Julia Laub

Description: A visually stunning book that explores the fundamentals of generative design, focusing on algorithmic design principles and their application to creative industries, including 3D printing. - Additive Manufacturing Technologies: 3D Printing, Rapid Prototyping, and Direct Digital Manufacturing

Authors: Ian Gibson, David W. Rosen, Brent Stucker

Description: This book covers a wide array of 3D printing technologies, including the role of generative design in additive manufacturing. It’s a comprehensive guide for both beginners and experts in the field. - Design for Additive Manufacturing: Developments in Generative Design

Authors: Martin Leary

Description: This book focuses specifically on how generative design is revolutionizing additive manufacturing. A must-read for anyone interested in applying AI-driven design principles in industries like automotive, aerospace, and healthcare. - AI-Powered Generative Design: Automating Creativity in Product Development

Authors: Daniel A. Brown, John Harris

Description: This book explores the impact of AI on design and manufacturing, diving deep into how generative design is changing the product development process.

Articles & Research Papers

- “Generative Design: AI Meets 3D Printing”

Source: MIT Technology Review

Description: An insightful article detailing how AI is transforming design processes in conjunction with 3D printing technologies, with real-world case studies. - “The Future of Design: Exploring the Power of Generative Algorithms”

Source: Forbes

Description: A forward-looking exploration of how AI and generative design will shape industries from architecture to product design, emphasizing the environmental and cost-saving benefits. - “AI-Driven Generative Design for Additive Manufacturing: A Review”

Source: Journal of Mechanical Design

Description: A technical paper reviewing recent advancements in AI-powered generative design for additive manufacturing, ideal for engineers and researchers looking for in-depth analysis. - “Case Study: Generative Design in the Aerospace Industry”

Source: Autodesk Redshift

Description: A practical case study showing how generative design was used to redesign parts for Airbus, leading to significant weight reduction and increased performance.

Tools & Software

- Autodesk Fusion 360

Website: fusion360.autodesk.com

Description: A leading tool for generative design and 3D printing. Fusion 360 integrates CAD, CAM, and CAE tools, allowing users to simulate and test designs before production. - nTopology

Website: ntopology.com

Description: An advanced design and engineering platform focused on generative design and additive manufacturing. It excels in creating complex geometries for industries like aerospace and medical devices. - Siemens NX

Website: plm.automation.siemens.com

Description: A comprehensive suite of CAD/CAM/CAE tools with integrated generative design and topology optimization features, widely used in industrial applications. - SolidWorks

Website: solidworks.com

Description: Known for its easy-to-use interface, SolidWorks has added generative design capabilities to its suite, enabling the development of optimized models ready for 3D printing. - ParaMatters

Website: paramatters.com

Description: A cloud-based generative design and topology optimization tool that specializes in lightweighting and manufacturing efficiency for industries such as automotive and aerospace.

Communities & Forums

- Generative Design Forum

Website: Generative Design Forum

Description: An active community of designers, engineers, and hobbyists discussing AI-driven generative design and 3D printing. It’s a great place to share ideas, get help with projects, and stay updated on the latest trends. - r/3DPrinting

Platform: Reddit

Description: A community dedicated to all things 3D printing, with discussions on generative design tools, best practices, and real-world applications of AI-driven innovation. - GrabCAD Community

Website: grabcad.com

Description: A platform where engineers and designers share their 3D models, tutorials, and insights, including generative design projects and resources for those in 3D printing and additive manufacturing.

Industry Conferences & Events

- Autodesk University

Website: autodesk.com

Description: An annual conference hosted by Autodesk, featuring sessions and workshops on the latest in generative design and 3D printing technologies. - Formnext

Website: formnext.com

Description: A leading international trade show for additive manufacturing and 3D printing, featuring exhibitors and speakers from top generative design companies and research institutions. - AMUG (Additive Manufacturing Users Group)

Website: amug.com

Description: A global event bringing together 3D printing professionals to share insights, discuss generative design trends, and collaborate on cutting-edge applications.