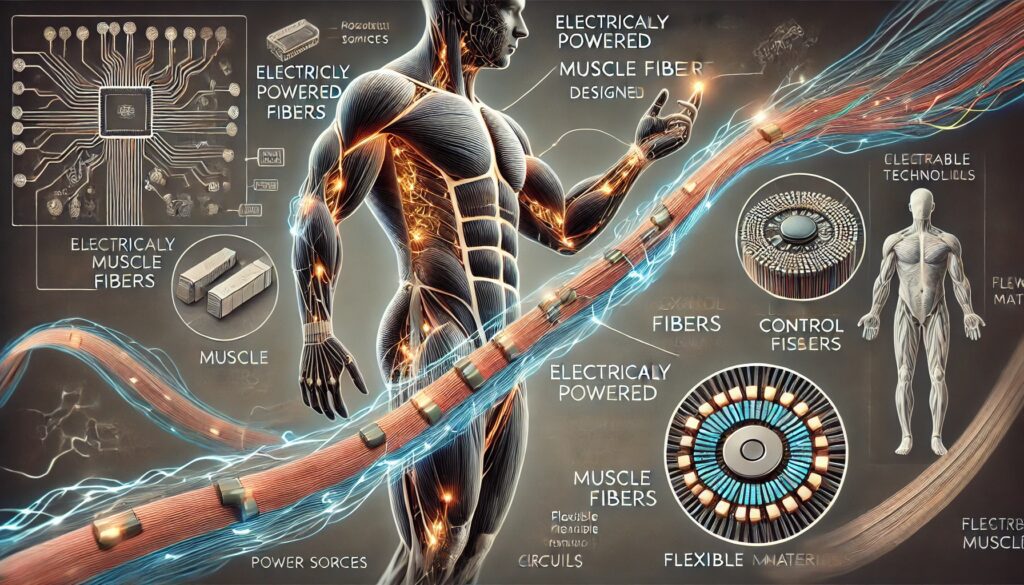

Electrically powered artificial muscle fibers are not just another incremental improvement in the world of robotics and wearable devices—they are poised to fundamentally transform these industries. To understand the full scope of this transformation, it’s essential to delve deeper into how these fibers work, the materials involved, their advantages over traditional systems, and the vast array of potential applications.

The Science Behind Artificial Muscle Fibers

Artificial muscle fibers are essentially engineered materials that can change their shape or size when stimulated by an external force, such as an electric current. These materials typically belong to a category known as electroactive polymers (EAPs). EAPs are polymers that exhibit a significant mechanical response when subjected to electrical stimulation, making them ideal for mimicking the behavior of biological muscles.

Two primary types of EAPs are used in artificial muscle fibers:

- Dielectric Elastomers (DEs): These are soft, elastic materials that deform when subjected to an electric field. DEs are known for their high energy density and efficiency, which makes them suitable for applications requiring large deformations and quick responses.

- Ionic Polymer-Metal Composites (IPMCs): These materials bend and flex when an electric field is applied. IPMCs are particularly interesting for applications where fine, controlled movements are necessary, such as in delicate robotic grippers or soft actuators in wearable devices.

Materials: The Backbone of Artificial Muscles

The performance of artificial muscle fibers hinges on the materials used. Some of the cutting-edge materials include:

- Carbon Nanotubes (CNTs): CNTs are cylindrical nanostructures made of carbon atoms. They are incredibly strong, lightweight, and conductive, making them ideal for creating fibers that can generate powerful contractions with minimal energy.

- Graphene: This single layer of carbon atoms arranged in a hexagonal lattice is not only one of the strongest materials known but also highly flexible and conductive. Graphene-based fibers can produce substantial force while remaining lightweight and flexible.

- Conductive Polymers: These polymers can conduct electricity and change their shape when an electric current is applied. They are often used in softer, more flexible artificial muscles that need to conform to complex shapes.

- Shape Memory Alloys (SMAs): SMAs can return to their original shape after deformation when heated. While not a polymer, SMAs are often used in conjunction with EAPs to enhance the performance of artificial muscles, particularly in applications where strong, durable materials are required.

Advantages Over Traditional Actuation Systems

Artificial muscle fibers offer several advantages over traditional actuation systems like motors and hydraulics:

- Flexibility and Adaptability: Traditional motors are rigid and require complex mechanisms to produce movement. In contrast, artificial muscles are inherently flexible and can easily adapt to a wide range of motions.

- Compactness: Motors and hydraulics are often bulky and heavy, limiting the design and portability of robotic systems. Artificial muscle fibers, however, can be made incredibly thin and lightweight, enabling more compact and portable designs.

- Energy Efficiency: Traditional motors consume a significant amount of energy, which can be a limiting factor in battery-powered devices. Artificial muscles, particularly those made from dielectric elastomers or carbon nanotubes, require much less energy, making them ideal for applications where energy efficiency is crucial.

- Scalability: Artificial muscle fibers can be scaled down to very small sizes, which is challenging for traditional motors. This opens up possibilities for micro-robots and nano-scale devices that can perform tasks with unprecedented precision.

Revolutionary Applications Across Industries

The versatility of artificial muscle fibers makes them suitable for a wide range of applications, each with the potential to revolutionize its respective industry:

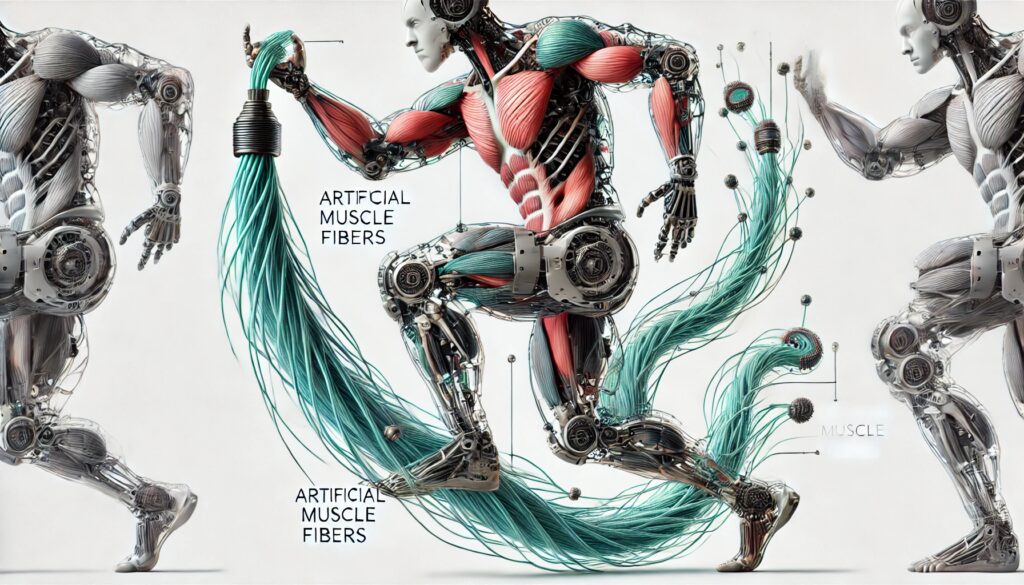

Robotics

In robotics, the integration of artificial muscle fibers could lead to a new generation of robots that are not only more agile but also more human-like in their movements. For example, soft robotics, a field focused on creating robots that mimic the softness and flexibility of living organisms, can greatly benefit from these fibers. Robots with artificial muscles can handle delicate objects, perform intricate tasks in unstructured environments, and even interact with humans more safely.

Wearable Devices

Wearable devices that incorporate artificial muscle fibers can offer unprecedented levels of comfort and functionality. Imagine a wearable exoskeleton that enhances a person’s strength and endurance without the bulky, rigid structures seen in today’s designs. Such a device could provide mobility assistance to the elderly or disabled, enabling them to perform tasks that would otherwise be challenging.

Smart clothing is another area ripe for innovation. Clothes made with artificial muscle fibers could automatically adjust their fit based on the wearer’s movements, ensuring maximum comfort. This technology could also be used in sportswear, where the fibers could provide targeted muscle support during intense physical activities.

Medical Devices

In the medical field, artificial muscle fibers hold promise for creating more natural and responsive prosthetics. Current prosthetics rely on motors and mechanical joints, which can be bulky and offer limited movement. Prosthetics powered by artificial muscles, however, could offer a level of dexterity and responsiveness that closely mimics natural limbs, greatly improving the quality of life for amputees.

Artificial muscles could also be used in implantable medical devices. For example, they could be integrated into artificial heart valves or pumps to help regulate blood flow in patients with cardiovascular issues.

Aerospace and Automotive

In aerospace and automotive industries, the lightweight and powerful nature of artificial muscle fibers could lead to more efficient systems. For instance, these fibers could be used in adaptive wing structures in aircraft that adjust their shape for optimal aerodynamics during flight, reducing fuel consumption and enhancing performance. In automotive applications, artificial muscles could replace traditional actuators in seats, mirrors, and other components, contributing to overall vehicle weight reduction and improving energy efficiency.

Consumer Electronics

Consumer electronics could also see significant advancements with the adoption of artificial muscle fibers. Devices like smartphones and tablets could incorporate these fibers to enable haptic feedback systems that provide more realistic tactile sensations. Additionally, artificial muscles could be used in foldable displays and transformable devices that change shape based on user interaction.

Exoskeletons for Mobility Assistance

Artificial muscle fibers are integrated into exoskeletons to enhance strength and flexibility, aiding individuals with mobility impairments. These exoskeletons use electrically actuated muscles, enabling users to walk or lift heavy objects with less effort.

Wearable Haptic Feedback Devices

Haptic suits and gloves equipped with artificial muscle fibers provide realistic touch sensations in virtual reality environments. Electrically powered fibers simulate touch, enhancing immersion for users in gaming or virtual training scenarios.

Biohybrid Robots

Biohybrid robots combine living cells with synthetic materials, using artificial muscle fibers to perform complex movements. This innovation is paving the way for advancements in medical robotics and prosthetics.

Artificial Limbs and Prosthetics

Electrically powered artificial muscles in prosthetic limbs offer more natural and precise movements. These muscles improve dexterity and control, helping amputees perform daily tasks with greater ease.

Smart Clothing for Rehabilitation

Wearable devices with embedded artificial muscle fibers aid in physical rehabilitation. These smart garments provide resistance and support during exercises, helping patients regain strength and mobility more effectively.

Overcoming Challenges and the Road Ahead

While the potential of artificial muscle fibers is immense, several challenges need to be addressed to bring this technology to the mainstream. Durability is a significant concern, as these fibers must withstand millions of cycles of contraction and expansion without significant wear. Researchers are exploring new materials and coatings to enhance the longevity of these fibers.

Manufacturing is another hurdle. Currently, producing high-quality artificial muscle fibers on a large scale is expensive and complex. Advances in nanotechnology and material science are expected to reduce costs and simplify production, making these fibers more accessible for commercial use.

Finally, integration into existing systems poses a challenge. Engineers need to design new systems that can fully exploit the capabilities of artificial muscle fibers, which may require rethinking traditional approaches to robotics and wearable devices.

Conclusion: Embracing a New Era of Technology

The rise of electrically powered artificial muscle fibers marks the beginning of a new era in robotics, wearable devices, and beyond. Their ability to mimic the natural movement of muscles, combined with their energy efficiency and flexibility, makes them a game-changer for numerous applications. As the technology continues to evolve, we are likely to see these fibers become an integral part of our daily lives, powering devices that were once the stuff of science fiction.

The future of technology is not just about more powerful processors or smaller chips—it’s about creating machines and devices that move, adapt, and respond in ways that feel almost organic. Artificial muscle fibers are at the forefront of this revolution, and the possibilities are as vast as our imagination.

Resources

Here are some resources to help you explore electrically powered artificial muscle fibers and their applications in robotics and wearable devices:

- Research Papers and Journals

- “Electroactive Polymers for Artificial Muscles”: This paper discusses the use of electroactive polymers (EAPs) in artificial muscle applications, focusing on their properties, challenges, and potential uses.

- “Carbon Nanotube-Based Artificial Muscles”: A comprehensive study on the use of carbon nanotubes in developing artificial muscle fibers, exploring their mechanical properties and potential in various industries.

- “Soft Robotics: Artificial Muscle Fibers in Action”: This article covers recent advancements in soft robotics, highlighting how artificial muscle fibers are being integrated into robotic systems.

- Books

- “Artificial Muscle Fibers: Materials, Applications, and Technologies” by Dr. John M. Madden: This book provides an in-depth look at the materials used in artificial muscles, their applications, and future trends.

- “Soft Robotics: Revolutionizing the Field with Artificial Muscles” by Cecilia Laschi and Barbara Mazzolai: A detailed exploration of soft robotics, focusing on the role of artificial muscle fibers in creating more flexible and adaptable robotic systems.

- Online Courses

- Coursera: “Robotics Specialization”: A course offered by the University of Pennsylvania that includes modules on artificial muscles and their application in modern robotics.

- edX: “Soft Robotics: Designing with Artificial Muscles”: This course focuses on the principles of soft robotics, with a significant emphasis on artificial muscle technology.

- Industry Reports

- “Artificial Muscles: Market Trends and Forecasts”: A report detailing the market outlook for artificial muscle fibers, including key players, emerging trends, and future predictions.

- “The Future of Wearable Technology: The Role of Artificial Muscles” by Gartner: An industry analysis that explores how artificial muscles are expected to impact the future of wearable devices.

- Websites and Blogs

- IEEE Spectrum: Regularly publishes articles and news related to robotics, including breakthroughs in artificial muscle technology.

- Soft Robotics Toolkit: A comprehensive resource for those interested in soft robotics, offering guides, research papers, and community discussions on artificial muscle fibers.

- Robohub: An online platform that covers the latest in robotics technology, including advancements in artificial muscle fibers.

- Videos and Webinars

- YouTube: “How Artificial Muscle Fibers Work in Robotics” – A visual explanation of the mechanics behind artificial muscle fibers and their application in robotics.

- TED Talks: “The Future of Robotics: Soft Robots with Artificial Muscles” – A TED Talk exploring how artificial muscles are changing the landscape of robotics.

- Webinars on IEEE Xplore: Various webinars on the topic of electroactive polymers and their applications in artificial muscles.

These resources will provide you with a deeper understanding of electrically powered artificial muscle fibers and their growing importance in the fields of robotics and wearable devices.