The intersection of generative AI and materials science is revolutionizing how we design and discover novel structures and compositions. This transformative technology accelerates innovation, reducing time and cost while opening doors to groundbreaking materials.

The Role of Generative AI in Materials Discovery

How AI Is Changing Material Design

Traditional methods of material discovery often rely on trial-and-error processes that take years. Generative AI, however, can analyze vast datasets and simulate thousands of possible outcomes in mere minutes. This capability allows scientists to predict material properties and optimize designs even before physical testing.

Machine Learning Models in Action

- Neural networks generate molecular structures based on desired properties like strength, elasticity, or conductivity.

- Reinforcement learning fine-tunes the discovery process by evaluating how well a structure meets set objectives.

For example, AI models have recently been used to predict thermoelectric materials for energy conversion, an application critical for sustainable energy solutions.

AI’s Impact on Computational Efficiency

Generative models reduce computational loads by focusing only on promising candidates. By narrowing the field, researchers save time and resources, boosting efficiency.

Applications in Developing Novel Structures

Designing Lightweight and Strong Materials

One of AI’s standout applications is creating lightweight materials for industries like aerospace and automotive. These materials need to be strong yet light enough to enhance performance and efficiency.

- AI has generated lattice structures that optimize weight and durability simultaneously.

- Companies like Boeing are exploring AI-generated metal alloys for next-gen aircraft.

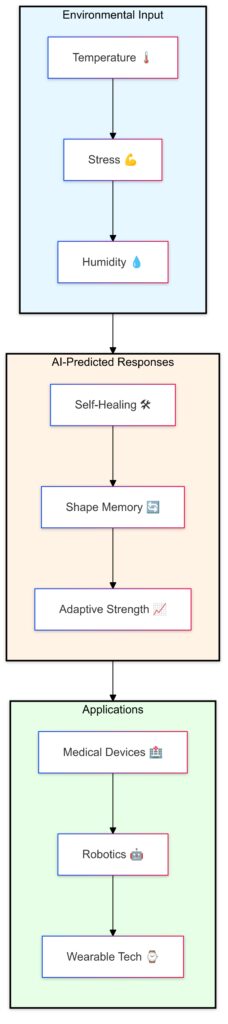

Smart Materials and Responsive Designs

Smart materials, such as self-healing polymers or shape-memory alloys, are gaining attention. AI models predict how these materials react to stimuli, such as temperature or stress, enabling tailored solutions.

- AI designs have led to advancements in programmable hydrogels used in medical devices.

- Researchers also use AI to discover adaptive architected materials for robotics.

Complex Crystal Structures

Generative AI can visualize and design complex crystal lattices, something that was nearly impossible without high-performance computing. This ability opens up opportunities in semiconductors, solar cells, and advanced coatings.

Compositions Tailored for Specific Needs

Predicting Optimal Alloys

Generative AI excels in creating custom metal alloys with enhanced properties like corrosion resistance or thermal stability. These compositions are essential for energy production, such as in wind turbines or nuclear reactors.

New Catalysts for Chemical Reactions

AI-designed catalysts have transformed industries like pharmaceuticals and fuel production. These catalysts reduce reaction times and energy requirements while improving yields.

- DeepMind’s AlphaFold is a prime example, aiding in protein structure prediction for better biochemical synthesis.

Accelerating Green Technologies

AI in Sustainable Materials

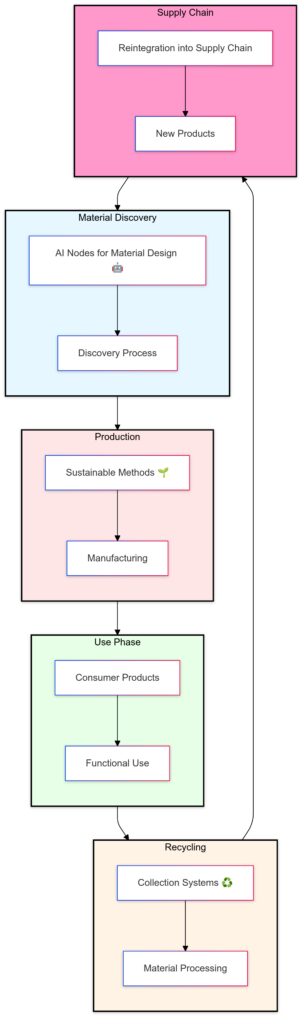

Sustainability is a growing priority, and green materials are at the forefront of innovation. Generative AI helps identify biodegradable polymers and alternatives to harmful plastics.

- Models assist in designing recyclable composites for construction.

- AI identifies eco-friendly ceramic materials for water filtration.

Decarbonizing Material Manufacturing

Generative AI also optimizes manufacturing processes to reduce carbon footprints. AI simulations refine energy use during production, aligning with net-zero goals in various industries.

Specific Use Cases of Generative AI in Materials Science

The integration of generative AI in materials science is yielding remarkable breakthroughs across industries. Below, we explore specific, real-world applications that demonstrate how AI is transforming materials research and development.

1. AI in Battery Materials for Energy Storage

Optimizing Lithium-Ion Batteries

Generative AI has revolutionized the search for better cathode and anode materials. AI models predict combinations that enhance energy density, charging speed, and lifespan.

- AI-driven discovery of solid-state electrolytes reduces safety risks and improves battery efficiency.

- Companies like Tesla and QuantumScape leverage AI to accelerate R&D for next-gen lithium-metal batteries.

Advancing Beyond Lithium

AI is now essential for exploring alternative chemistries like sodium-ion, magnesium-ion, or even organic batteries. These options could provide more sustainable and abundant solutions.

Addressing Recycling Challenges

AI helps design batteries with recyclable components by predicting how materials behave during disassembly. This supports the shift toward a circular economy in energy storage.

2. Generative AI in Biomedical Materials

Designing Personalized Implants

Generative AI is being used to create patient-specific implants made from bio-compatible materials.

- 3D-printed bone scaffolds made with AI-suggested composites promote faster healing and better integration.

- AI designs customized dental implants that consider the patient’s unique oral structure and bite.

Drug Delivery Systems

AI is pivotal in creating nanoparticles for targeted drug delivery. These particles can carry medications directly to diseased cells, reducing side effects and improving treatment outcomes.

- AI-generated materials have improved drug-release profiles in oncology treatments.

Tissue Engineering Innovations

In regenerative medicine, AI designs scaffolds that mimic natural tissues for applications like skin grafts or organ regeneration. Materials with optimized pore sizes and biodegradability ensure better cell growth.

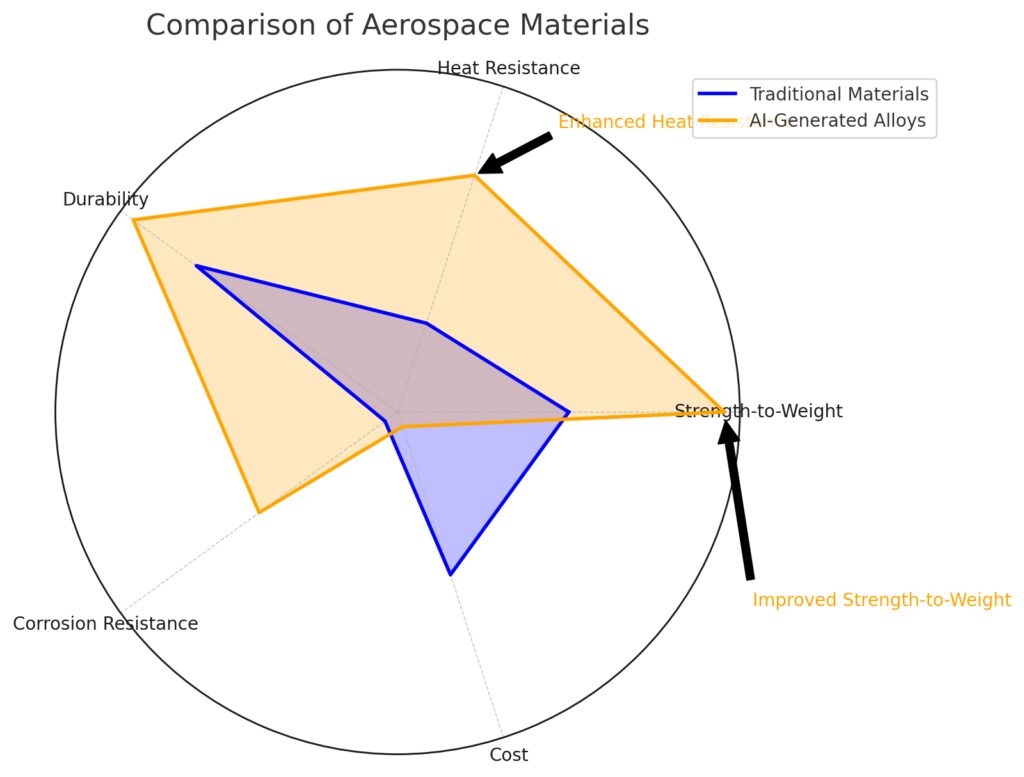

3. AI in Aerospace Material Innovation

Strength-to-Weight Ratio:

AI-Generated Alloys show significant improvement, making them ideal for aerospace applications.

Heat Resistance:

Enhanced in AI-Generated Alloys, crucial for handling extreme temperatures.

Durability and Corrosion Resistance:

Both materials are competitive, with a slight edge for AI-Generated Alloys.

Cost:

Traditional Materials are currently more cost-effective, highlighting a trade-off.

Highlights:

Enhanced Heat Resistance: Makes AI-Generated Alloys suitable for high-stress environments.

Improved Strength-to-Weight Ratio: Directly impacts efficiency and performance.

Superalloys for Extreme Environments

Generative AI identifies heat-resistant superalloys capable of withstanding extreme temperatures and stresses in jet engines.

- High-entropy alloys (HEAs) generated by AI have unique properties, such as enhanced strength-to-weight ratios.

- Aerospace firms like Airbus use AI to explore composites for hypersonic vehicles.

Thermal Protection Systems

AI-designed ceramic matrix composites (CMCs) are transforming heat shields and insulation materials for spacecraft. These materials ensure durability during reentry, where temperatures exceed 3,000°F.

Lightweight Structures

The aerospace industry benefits from AI-optimized lattice designs that reduce weight without compromising strength. These materials are used in airframe construction and satellite components.

4. Generative AI in Advanced Electronics

Semiconductors and Quantum Materials

AI accelerates the discovery of 2D materials like graphene and molybdenum disulfide, which enable faster and more efficient electronic devices.

- AI-designed heterostructures improve transistor performance for next-generation computing.

- Generative models aid in creating quantum dots and topological insulators for quantum computing applications.

Flexible and Wearable Electronics

Wearable tech benefits from AI-driven discoveries of flexible, durable, and conductive polymers.

- Generative AI has enabled the creation of stretchable circuits for health-monitoring devices.

- AI-generated materials are essential for self-healing electronics, which can repair after damage.

High-Performance Optoelectronics

AI is advancing materials used in OLED displays and solar cells, optimizing energy efficiency and lifespan. For example, AI simulations predict which organic molecules will emit the brightest light or absorb the most solar energy.

5. Generative AI in Construction and Infrastructure

Sustainable Concrete Mixtures

Concrete is a significant contributor to global CO2 emissions, but AI is helping to change that.

- Generative models design concrete mixtures using alternative binders like fly ash or slag, reducing carbon footprints.

- AI predicts the long-term durability of green concrete, ensuring safety and performance.

Self-Healing Infrastructure Materials

AI aids in the development of materials that automatically repair cracks in roads and bridges. These self-healing concretes incorporate microbial agents or polymer capsules that activate when damage occurs.

Lightweight and Insulating Materials

For construction in extreme climates, AI is designing aerogels and phase-change materials that provide superior insulation while minimizing weight.

6. AI for Advanced Coatings

Anti-Corrosion Coatings

Generative AI suggests nanostructured coatings that protect metals from corrosion, particularly in harsh environments like oil rigs or marine vessels.

- AI-generated ceramic coatings extend the lifespan of tools in manufacturing.

Energy-Efficient Coatings

AI develops materials for reflective coatings used in buildings to reduce heat absorption and lower energy costs. Similarly, low-emissivity coatings on windows enhance thermal insulation.

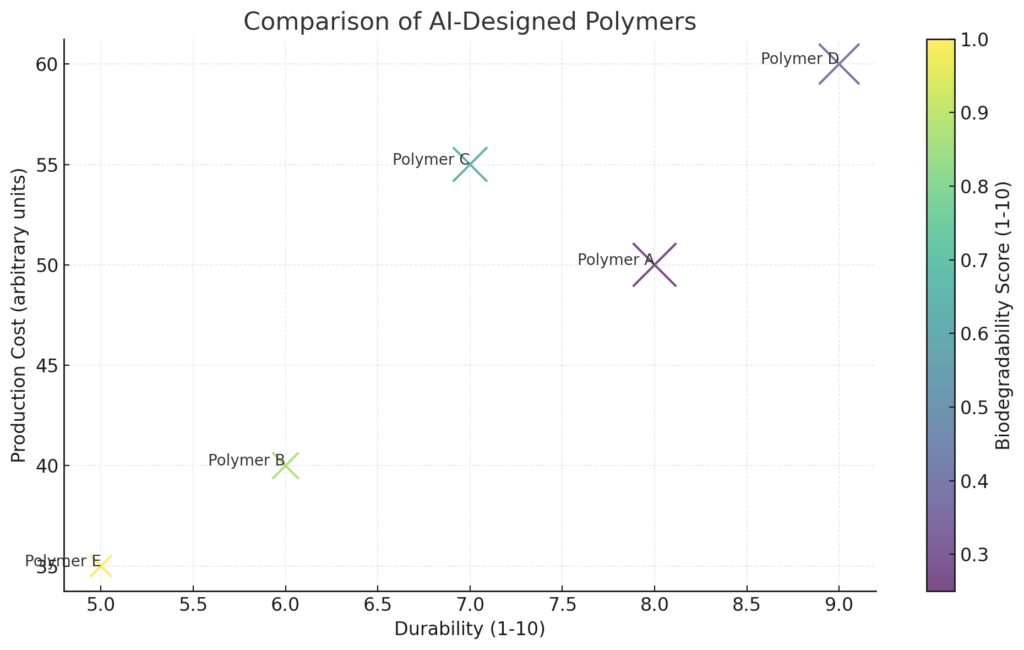

7. AI for Sustainable Polymer Development

Properties of AI-generated sustainable polymers compared by durability, biodegradability, and environmental impact.

Bioplastics and Degradable Polymers

AI is vital in designing bioplastics that are durable for use yet degrade harmlessly after disposal.

- Generative models suggest formulations for polyhydroxyalkanoates (PHAs) and polylactic acid (PLA) used in packaging.

Functional Polymers for Water Purification

Polymers designed with AI are advancing water treatment technologies. These materials efficiently remove contaminants like heavy metals or microplastics.

Conductive Polymers

AI aids in creating conductive polymers used in sensors, batteries, and electronic skin for robotics.

Challenges and Future Trends in Generative AI for Materials Science

While the potential of generative AI in materials science is immense, it comes with challenges that require attention. Simultaneously, emerging trends highlight exciting opportunities to further revolutionize this field.

Challenges in Applying Generative AI to Materials Science

1. Data Quality and Availability

AI models rely heavily on high-quality, labeled datasets to make accurate predictions. However, materials science often suffers from:

- Sparse data: Some materials, especially novel ones, lack sufficient experimental data.

- Inconsistent data formats: Data from different labs or simulations may vary in structure and measurement standards.

- Expensive generation: Experimental validation of AI predictions is costly and time-consuming.

Without robust datasets, even the most advanced AI models can falter.

2. Complexity of Material Behavior

Materials exhibit behaviors influenced by atomic interactions, external conditions, and long-term usage. Capturing these phenomena requires advanced simulations that are computationally intensive.

- For instance, predicting a material’s performance under extreme conditions or over decades is still beyond many models.

3. Computational Limitations

Training and running generative AI models, especially for large-scale simulations, demands significant computational resources. Access to high-performance computing (HPC) or quantum computing remains a barrier for many researchers.

4. Interpretability of AI Models

Generative models, particularly neural networks, often function as black boxes. While they generate accurate predictions, understanding why a specific material or structure is optimal remains unclear. This lack of interpretability can hinder trust and adoption in critical applications like aerospace or medicine.

5. Validation and Scalability

Predictions from AI models must undergo rigorous experimental validation. However:

- Experimental setups may not fully replicate simulated conditions.

- Scaling up from lab-level discoveries to industrial applications introduces unforeseen challenges.

6. Ethical and Environmental Concerns

- Bias in datasets: If AI models are trained on biased datasets, they may overlook viable but underrepresented material types.

- Resource-intensive computations: The energy demands of running AI models may conflict with sustainability goals, especially in fields like green materials.

Future Trends in Generative AI for Materials Science

1. Integration with Quantum Computing

Quantum computing is expected to address the computational limitations of generative AI. Quantum algorithms will enable simulations of complex quantum phenomena, making it possible to design materials at the atomic scale with unprecedented accuracy.

- Applications: Quantum chemistry, superconductors, and exotic quantum materials.

2. Automated Labs and AI Collaboration

The rise of autonomous labs, powered by robotics and AI, will streamline material discovery. These labs can:

- Perform high-throughput experiments based on AI predictions.

- Continuously feed experimental results back into models for improved accuracy.

3. Advanced Multi-Scale Modeling

Future AI systems will combine multi-scale simulations, bridging atomic, molecular, and macroscopic material behaviors.

- This integration will improve predictions for materials used in complex systems like microelectronics or biomedical implants.

4. AI for Circular Economy Materials

Generative AI will play a crucial role in advancing the circular economy.

- Designing recyclable materials that maintain performance over multiple cycles.

- Identifying alternatives to rare earth elements for sustainable manufacturing.

5. Open-Source Collaborations

Open-source platforms for materials data and AI models will democratize access, enabling broader collaboration. Initiatives like the Materials Project and Open Catalyst Project are paving the way for shared advancements.

6. Real-Time AI Optimization

Generative AI will soon be integrated into manufacturing processes for real-time optimization. This innovation will adjust material properties during production to meet performance goals dynamically.

7. Ethical AI in Materials Science

Ethical AI practices will gain prominence, ensuring models are unbiased, transparent, and environmentally conscious.

- Adoption of green AI principles: Using energy-efficient algorithms and cloud-based systems with minimal environmental impact.

8. Expansion into New Domains

Generative AI will extend its influence into emerging material categories:

- Metamaterials: Artificial materials with properties not found in nature, like invisibility cloaks or super lenses.

- Bio-inspired materials: Mimicking nature’s designs, such as spider silk or nacre, for lightweight, durable solutions.

- Energy-harvesting materials: AI will design materials that convert ambient energy (e.g., vibrations, heat) into usable electricity.

The Road Ahead

Generative AI’s role in materials science will continue to grow, bridging gaps between theory and experimentation, speed and precision, and innovation and sustainability. However, navigating challenges like data limitations and computational costs is crucial. By addressing these barriers, generative AI will unlock a new era of materials that reshape industries and enhance lives.

Summary: Generative AI in Materials Science

Generative AI is revolutionizing materials science by accelerating the discovery and design of novel structures and compositions. It predicts material properties, optimizes designs, and reduces the trial-and-error nature of traditional research. Key applications include creating advanced battery materials, biomedical implants, lightweight aerospace alloys, and green polymers.

However, challenges like data scarcity, computational demands, and the interpretability of AI models persist. Additionally, the need for experimental validation and scalability from lab to industry poses hurdles. Ethical and environmental concerns, such as model bias and energy use, require attention.

Future trends promise exciting advancements, such as integrating AI with quantum computing, developing autonomous labs, and enabling real-time optimization during manufacturing. AI’s role in promoting the circular economy, advancing metamaterials, and designing energy-efficient solutions will continue to grow.

By overcoming challenges and leveraging emerging technologies, generative AI is poised to drive a new era of sustainable and innovative material discoveries.

FAQs

Can AI predict entirely new materials?

Yes, AI can design materials that do not yet exist. For instance, it has created high-entropy alloys with unique combinations of strength and flexibility. AI also explores programmable materials, like shape-memory polymers, that adapt to environmental stimuli.

What role does quantum computing play in this field?

Quantum computing enhances AI’s ability to simulate complex material properties, especially at the atomic scale. This capability is vital for discovering advanced materials like room-temperature superconductors or quantum dots used in next-gen electronics.

Is AI making materials research faster?

Absolutely. Traditional methods of material discovery can take years, but AI reduces this timeline significantly. For example, designing and testing a new battery electrode that previously required months can now be achieved in weeks through AI simulations.

How does generative AI promote sustainability?

Generative AI contributes to sustainability by:

- Designing recyclable materials, such as reusable polymers.

- Reducing energy-intensive experiments through predictive modeling.

- Identifying efficient alternatives to rare or toxic elements, such as cobalt-free batteries.

How does AI improve battery technologies?

Generative AI optimizes the development of high-capacity battery materials by predicting new combinations of electrodes, electrolytes, and separators. For example, AI has been instrumental in advancing solid-state batteries, which are safer and more efficient than traditional lithium-ion batteries. Additionally, it explores sodium-ion batteries as a sustainable alternative to lithium-based solutions.

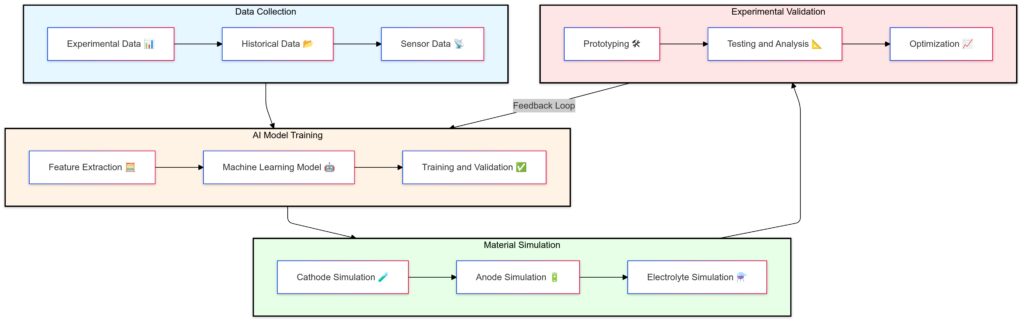

Data Collection:

Sources: Experimental data, historical records, and sensor inputs.

AI’s Role: Aggregates diverse datasets for model training.

AI Model Training:

Processes: Feature extraction, machine learning, and validation.

AI’s Role: Identifies patterns and relationships critical for battery performance.

Material Simulation:

Components Simulated:Cathodes 🧪

Anodes 🔋

Electrolytes ⚗️

AI’s Role: Predicts material behaviors under various conditions.

Experimental Validation:

Steps: Prototyping, testing, and optimization.

AI’s Role: Guides prototyping and iterative refinements based on data feedback.

Key Features:

Icons: Represent battery components and critical tasks for visual clarity.

Flow Lines: Indicate the iterative feedback loop from validation back to AI training.

Can AI help reduce material waste in manufacturing?

Yes, AI minimizes waste by designing materials that require fewer raw resources or can be recycled efficiently. For instance, AI suggests production methods that reduce material offcuts in automotive parts or develops modular composites for easy disassembly and reuse in construction.

What are examples of AI-driven breakthroughs in smart materials?

Generative AI has enabled several advances in smart materials, including:

- Self-healing materials that repair cracks autonomously, used in infrastructure and aerospace.

- Shape-memory alloys for robotics and medical devices that return to a programmed shape after deformation.

- Programmable hydrogels for applications in drug delivery and soft robotics.

How does AI contribute to renewable energy technologies?

Generative AI helps design materials for solar panels, such as perovskite materials, which offer better efficiency at lower costs. It also identifies coatings that enhance wind turbine performance or reduce wear in hydropower systems. AI even optimizes materials for thermal energy storage, critical for managing intermittent renewable energy sources.

Can AI design materials for extreme environments?

Absolutely. AI has successfully developed materials that withstand extreme conditions, such as:

- Heat-resistant ceramics for spacecraft reentry shields.

- Corrosion-resistant alloys for deep-sea exploration.

- Radiation-resistant composites for nuclear reactors and space missions.

How is generative AI transforming healthcare materials?

AI is a game-changer in healthcare materials by enabling:

- Custom implants, such as titanium bone plates designed to match a patient’s anatomy.

- Biodegradable sutures that dissolve over time, eliminating the need for removal.

- Antimicrobial coatings for medical devices to reduce infections.

Are there risks of bias in AI-generated materials?

Bias can arise if the training data disproportionately represents certain material types or applications. For example, AI might prioritize commonly used materials like steel alloys over emerging options like carbon-based nanomaterials. Addressing this requires diverse, well-curated datasets.

How does AI handle the complexity of molecular structures?

Generative AI uses neural networks and graph-based models to understand and predict the behavior of complex molecular structures. For instance, AI can visualize and optimize multi-layer crystal lattices used in semiconductors or advanced coatings for electronics.

What are the economic benefits of using AI in materials science?

AI reduces costs by:

- Shortening research timelines for new materials, saving on labor and experimental expenses.

- Increasing manufacturing efficiency, cutting waste and energy consumption.

- Creating innovative materials that lead to high-margin products in industries like aerospace and electronics.

Can AI design materials with multi-functional properties?

Yes, AI excels at designing materials that serve multiple functions. Examples include:

- Energy-absorbing composites used in car safety systems that are also lightweight for fuel efficiency.

- Thermal and electrical conductors for electronics that also have structural strength.

- Bio-compatible hydrogels that act as scaffolds for tissue growth and deliver drugs.

Is AI advancing materials for quantum computing?

Generative AI is integral to discovering materials for quantum technologies. It identifies topological insulators and superconductors essential for stable quantum operations. AI also optimizes materials for qubits, the building blocks of quantum computers, ensuring better coherence times and performance.

What’s the role of AI in additive manufacturing (3D printing)?

AI enhances 3D printing by designing materials tailored for additive processes. It creates optimized filament compositions, predicts how materials will behave during printing, and reduces defects like warping or delamination. AI-designed materials enable innovations like lightweight aerospace parts and custom prosthetics.

Resources

Research Papers and Publications

- “The Role of Artificial Intelligence in Materials Science” (2022)

A comprehensive review of how AI is transforming material discovery and design, covering algorithms, challenges, and applications.

Link to Research - “Deep Learning for Accelerated Material Discovery” (2023)

Focused on how neural networks enable the prediction of material properties and accelerate the discovery process.

Published in Advanced Materials. - “Machine Learning for Sustainable Materials”

A study on how AI contributes to developing green materials, such as recyclable polymers and low-carbon concrete. - “AlphaFold and Its Applications in Material Science”

While focused on proteins, this paper illustrates the power of AI models like AlphaFold for predicting molecular structures, with applications in drug delivery systems and catalyst design.

Online Tools and Databases

- The Materials Project

A database offering open-access computational materials data, powered by machine learning and AI. It provides predictions on material stability, electronic structures, and more.

Visit Site - Open Catalyst Project

A cutting-edge initiative using AI to develop catalysts for renewable energy, focusing on CO2 reduction and hydrogen production.

Visit Site - MATIN (Materials Informatics)

A platform for AI-driven materials informatics, offering tools to explore datasets and build predictive models for material properties.

Visit Site - ASE (Atomic Simulation Environment)

A Python library for setting up, running, and analyzing materials simulations, frequently used with AI models.

Software and Frameworks

- Materials Studio

A commercial tool combining molecular modeling and AI to simulate materials at atomic and molecular levels. - Chemoinformatics Tools like RDKit

RDKit is a free, open-source toolkit used for AI and machine learning in chemistry and materials science.

Visit Site - DeepChem

An open-source Python library for deep learning in drug discovery, quantum chemistry, and materials science.

Visit Site

Learning Platforms

- edX: AI in Materials Science

Offers online courses like “AI for Materials Discovery” by leading universities, focusing on real-world applications.

Visit edX - Coursera: Materials Informatics and AI

Courses like “Introduction to Materials Informatics” cover generative AI tools in materials science.

Visit Coursera - Kaggle Datasets and Competitions

Kaggle hosts challenges like predicting material properties and optimizing compositions, offering datasets and community support.

Visit Kaggle

Industry Case Studies

- Tesla’s AI in Battery Design

Tesla leverages AI to optimize battery chemistries for electric vehicles, focusing on long-range and sustainable solutions. - Airbus and Generative AI for Lightweight Composites

Airbus uses AI to design aerospace-grade alloys that are lighter and stronger, improving fuel efficiency. - DeepMind’s Contribution to Quantum Materials

DeepMind applies its generative AI expertise to discover topological insulators for quantum computing. - BASF’s AI-Powered Chemical Discovery

BASF employs AI to create new polymer blends for coatings and plastics with enhanced durability and eco-friendliness.

Communities and Conferences

- Materials Research Society (MRS)

Hosts annual conferences focusing on AI and materials science.

Visit Site - AIChE (American Institute of Chemical Engineers)

Regular webinars and workshops on generative AI applications in materials and chemical engineering.

Visit Site - LinkedIn Groups: Materials Informatics & AI

Join communities discussing AI-driven innovations in materials science, such as “AI in Materials Design” and “Materials Informatics Forum.”